- Portfolio News

- 05 February, 2025

Today we’re happy to announce that 3D Hubs, a Balderton portfolio company, has been acquired by Protolabs in a deal worth $330M in cash and shares.

Amsterdam-based 3D Hubs was founded with a single goal in mind, to connect designers and manufacturers to give anyone, anywhere the power to create anything they wanted. For the last seven years, Bram, Brian, Filemon and the team have done this independently, but in Protolabs they have found a strong partner to continue on their mission as a combined entity.Balderton led both the Seed and Series A in the company, and I was fortunate to sit on the board from the very first meeting, when the company was just three people in a cluttered shared office space, to the last one where we had virtual attendees from our offices around the globe. The strategic reasons for this acquisition will be well covered elsewhere, but we wanted to share a few perspectives from our experience with the company for other entrepreneurs who are at the beginning of their journey building the next-generation of marketplaces.

1) Visionaries and Missionaries

Generally, company founders fall into two camps. Some are missionaries, they come at industries they have never worked in with a new idea and can be incredibly successful. But Bram, Brian, the first two founders of 3D Hubs are visionaries. Both had worked in industrial design, started their careers in manufacturing at 3D Systems, and were designing and selling 3D printed products from the second they could get access to a machine. They quit promising jobs early in their careers because they truly believed in a future of highly personalised and decentralised manufacturing, and wanted to be part of that change.The first time I met Bram, he had just come back from delivering an order to a client in Amsterdam on his bicycle, and such was his passion that by the end of the meeting I had ordered my first 3D print (a Kermit-green bracelet, they couldn’t help me with my bad taste). It was hard to imagine these same machines would be creating parts for satellites in a few years. But starting and building a company in an emerging field of technology like 3D manufacturing requires a supernatural level of belief in the future, and both have that in spades. This, as with most great companies, was the fundamental spark for all the rest and the main reason for our investment.

2) Communities and Commodities

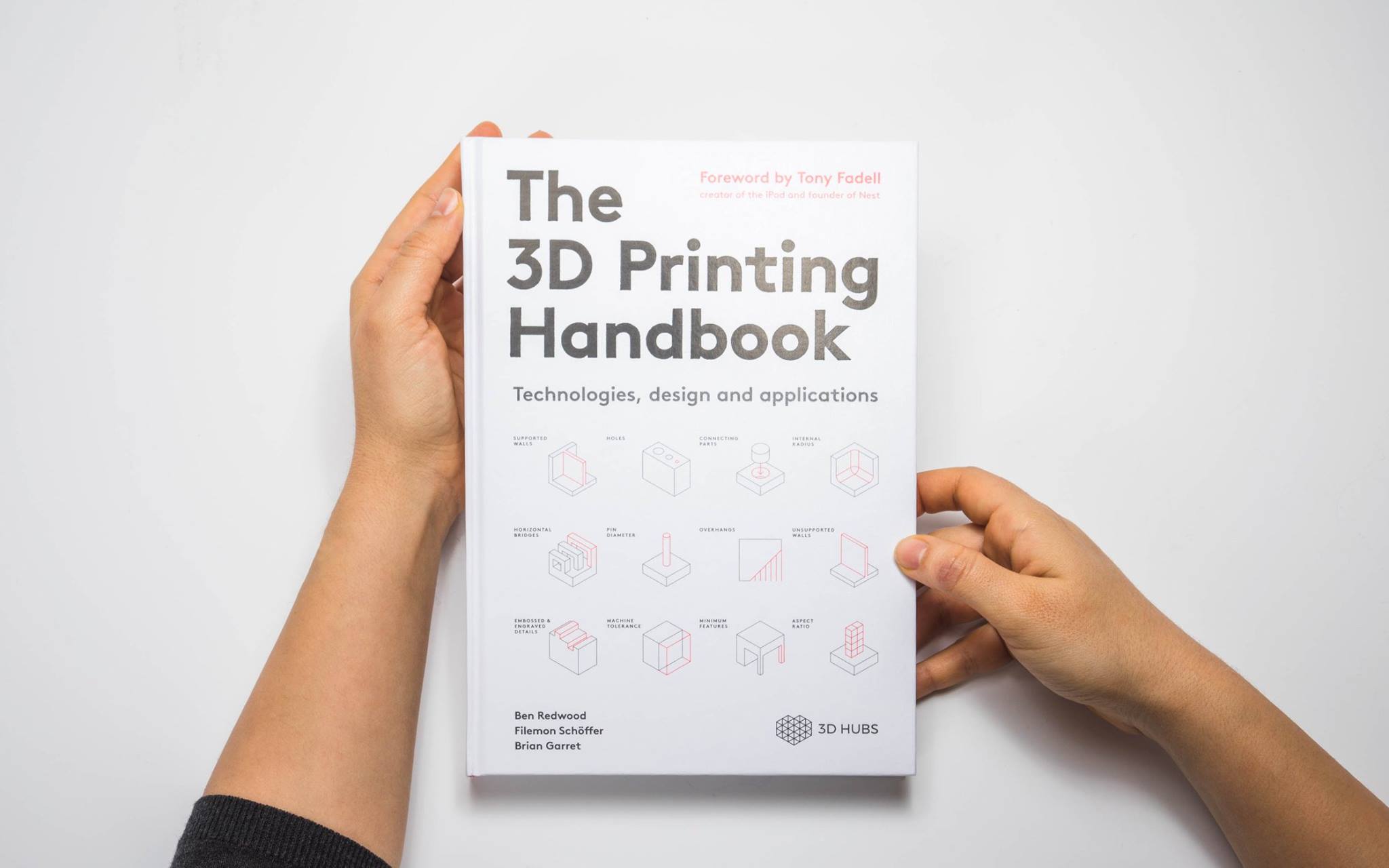

When 3D Hubs started, they were a marketplace connecting two fairly niche groups, designers and hobbyists with 3D-printer owners. We had, and still have, an investment thesis that both sides of this marketplace were due to expand rapidly, as design tools become more accessible and new manufacturing machines more affordable. Within a year of starting, 3D Hubs had tens of thousands of ‘hubs’, small manufacturers spread across every country in the world, and they were processing 1,000s of parts a day. The initial success was amazing, however, such rapid growth quickly invited competition, with a number of similar marketplaces, often better funded, appearing overnight, which ran the risk of turning our marketplace into a commodity.Rather than investing the entire budget in performance advertising as some competitors were doing, the team focussed instead on building the community around these new users and producers from the bottom-up. They used the platform to gather user’s views and performance data on the different machines and materials, they created a monthly guide on which printers were performing best for different applications. Hubs, which ranged from garden sheds to large factories ( and for a while even the Balderton office, although we never got more than 3-stars ) were given reviews, but also personalised guidance on how to improve. In fact, they wrote the literal book on 3D Printing.

The 3D Printing Handbook provides practical advice on selecting the right technology and how-to design for 3D printing

In the face of competition, rather than spend their capital on transactional marketing, they built resources for a community of both semi-professionals and large corporations which resulted in much better NPS, retention and radically lower acquisition costs for new users, and as a result greater loyalty from suppliers too.

3) Building broad then building deep

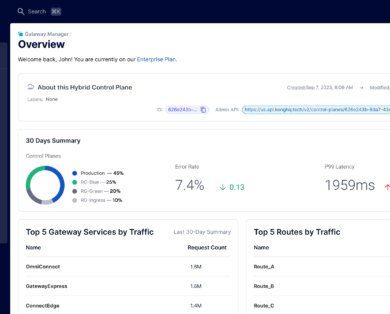

In fast-innovating hardware cycles, such as 3D printers and CNC machines, we at Balderton believed it was better to be in the software-layer than trying to picking the winning hardware. Despite a frenzy of funding into new machinery in 2012-2015, the promise of personalised home 3D printers struggled to match the quality and consistency needed, and it was clear that in the immediate future, the supply side of the Hubs marketplace was best served by professional and semi-professional suppliers who had access to higher-end machines. This market was growing fast, but it was more concentrated than the global community they had built initially, and as a result, it was clear that the product would have to adapt too.Holding on to the demand-side of the market was an even greater challenge because of its breadth. 3D Hubs was now helping people from bedroom-designers to rocket-scientists to prototype and ship parts in metals, plastic, wood and other materials. Having a strong community alone wasn’t enough, and so they started to build depth into the platform using the millions of data points generated in the previous years. From an initially static site, 3D Hubs built an incredibly powerful platform which could help creators render, test, share and dynamically price almost any part in almost any material for production anywhere in the world. The users came back to the platform not just because of the need for a product, but because of the depth and quality of the services on top of that, giving the company an increasingly deep technical and data moat, strengthening the company’s economics and improving customer’s feedback in the process.

4) A 20-year plan

One of the biggest challenges when starting a business is balancing the beautiful dream with the messiness of day to day operations.Almost every board meeting at 3D Hubs started with a reminder of the company’s mission, to be the biggest, most accessible factory in the world, without owning a single machine. Much of our last board meeting was focussed on the strategic decisions and product launches required to drive the future of automated and distributed manufacturing in the coming years. It was only after we spoke about the big product vision we had that we ever got into the immediate details of the business. We had big plans for 2021 after a very solid 2020 despite global disruption, and had not planned for a merger of the company. However, in ProtoLabs the team found a partner that had a similar vision of the future and one that could radically accelerate their plans.Having a dream isn’t enough to build a hugely successful company, but it is a necessity, and Bram, Brian, Filemon and the entire 3D Hubs team managed to balance a 20-year vision with a day-to-day practicality which has made 3D Hubs such a success.We look forward to watching the future of the company as they continue to give everyone the access to create whatever they can dream of too.

The 3d Hubs team

Read more about the news: