- Portfolio News

- 25 April, 2025

The investment included participation from existing and new investors, including the Qatar Investment Authority, Partners in Equity, Hanaco, Atomico, Lightrock and Bonnier.

The additional capital will serve to expand the deployment of the company’s vertical farms in the U.S., Canada, Japan and Europe, and to enter new markets in Asia-Pacific and the Middle East with both in-store farming units and Infarm Growing Centres.

Balderton first led Infarm’s Series A in 2018.

In 2023, Infarm will open its first Growing Centre in Qatar, where it will harvest tomatoes, strawberries and other fruiting crops besides herbs, salads and leafy greens.

The current food system is broken. Vertical farming and the Infarm system provide a sustainable solution to feed a growing population in a way that’s much better for the planet and is far more resilient and flexible in the face of climate uncertainty and supply chain disruption.

Erez Galonska Co-founder & CEO, Infarm

Building a global farming network of our climate-resilient vertical farms is a core mission at Infarm, which is why we’re excited to announce this latest funding round. This strategic investment will support our rapid global expansion and bolster our R&D so that we can grow more varieties of crops close to consumers across Europe, Asia, North America and the Middle East. It’s another step towards meeting our ambition of growing the entire fruit and vegetable basket in the near future, providing premium products at affordable prices to everyone.

Erez Galonska Co-founder & CEO, Infarm

Infarm Growing Centres are Infarm’s flagship production units. The spaces connect multiple vertical farming modules, offering the equivalent of about 110,000ft2/10,000m2 of growing capacity, with a distribution centre that ensures quick delivery to supermarkets. Infarm also builds smaller in-store farming units for grocery stores, making the shopping experience more dynamic for consumers. Both designs were developed to maintain superior freshness, while consuming considerably fewer resources than soil-based agriculture.

In addition to the more than 75 different varieties of herbs, salads and leafy greens Infarm currently produces, the company is working to expand its portfolio with 40 new crops next year such as mushrooms, cherry tomatoes, peas and strawberries.

Infarm’s cloud-connected farming network can be scaled rapidly and requires less upfront capital than its peers. The company’s proprietary modular technology can be deployed in as little as six weeks to transform a space the size of a living room (c. 430ft2/40m2) into an urban vertical farm that produces more than 500,000 plants per year – the equivalent of a football field-worth of crops. This new farming model can be as much as 400 times more efficient than soil-based agriculture and uses no chemical pesticides. It requires 95% less land and uses 95% less water by recycling water and nutrients and using the evaporated water of the plants. Because crops are grown directly in cities, they also require 90% fewer food miles to get to consumers’ plates.

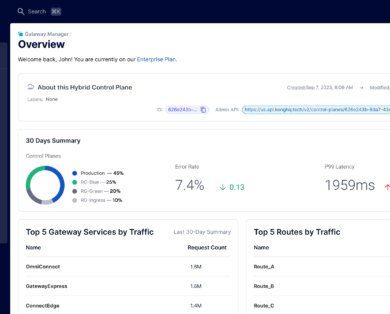

Each farm is equipped with numerous lab-grade sensors that have collected more than 60 billion data points from its global farming network. The farms upload information to the

company’s cloud, the so-called “farm brain.” Using patented software and artificial intelligence, Infarm’s crop science team analyses the numbers to continuously update the

growing environment in each module and improve factors like yield, quality and nutritional value. In the last three years through the analyses made possible by the “farm brain”, the

company reduced production costs by 80% and improved yield by more than 250%.